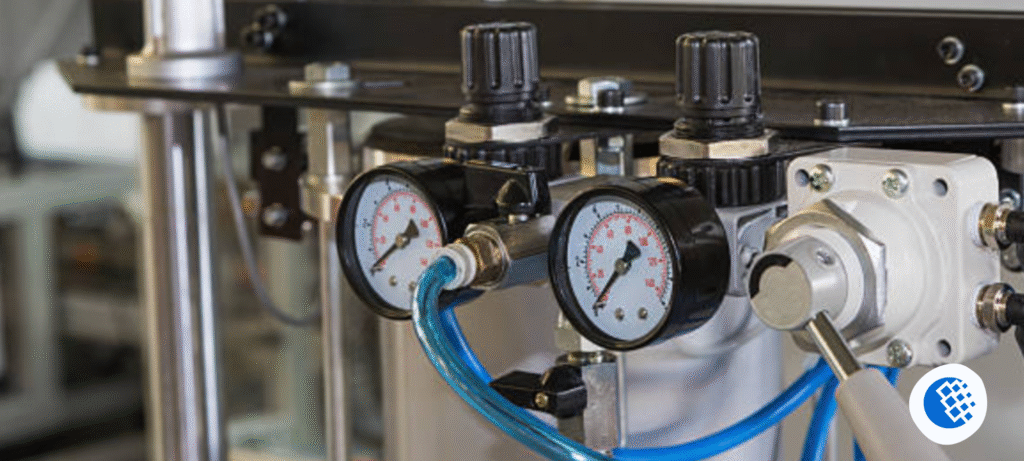

In the Industrial Automation landscape, even minute details can drastically impact performance. Air filter regulators are a great example as they help to ensure clean and consistent delivery of compressed air throughout systems, making them truly critical. They serve an often overlooked function of both filtering liquid or solid contaminants from the air stream, reducing parm pressure to required levels while also serving as a regulator element for air flow/exhaust in other applications.

For an automation parts supplier, understanding the multifunctionality and importance of air filter regulators will lead to optimal sourcing choices that reduce maintenance costs while enhancing operational productivity and uptime.

What Are Air Filter Regulators and Why Are They Important?

Air filter regulators are crucial because they combine two separate tasks into one unit by removing particulates and moisture through filtration from TF606-S series vent filters while maintaining the downstream air pressure at a consistent needed level. These components work actively with pneumatic systems to make sure air powered tools like actuators, valves and compressors work smoothly without breaking down prematurely from dirt or wear due to pressure change risks.

Dust, oil, and water vapor contaminants can stem from compressors, aging pipes in the system, or even external environments. If these substances are not properly filtered and regulated it may lead to:

- Damage to sensitive pneumatic tools

- Decreased cycle speed and operational efficiency

- Increased system wear and tear

- Frequent unscheduled system shut downs

Engineers can improve reliability, performance consistency, and increase the longevity of systems by using air filter regulators at strategically designated points within the system.

Automotive Assembly Lines

The automotive assembly line is perhaps one of the most demanding environments for pneumatic equipment. At this stage in any modern automobile manufacturing plant thousands of robotic arms have to perform welding operations while air torque wrenches spend milliseconds unfastening bolts on an engine. Each tool relies purely on clean controlled air. In addition to these systems, components like custom bellows for machinery play a crucial role in protecting moving parts from dust, debris, and contaminants. These durable covers ensure the longevity and precision of automated equipment, minimizing downtime and maintenance costs.

Air filter regulators are essential for critical functions:

- Robotics arm actuation

- Paint spray systems

- Tire inflation lines

- Air tools utilized during engine assemble

In a single sentence: Automotive manufacturers heavily depend on air filter regulators alongside other precision parts from a vetted automation parts supplier which join up with high-speed assembly lines seamlessly without contamination interference.

Even slight pressure drops or contamination in the air stream could cause significant delays or introduce defects into the quality of work performed. These filters regulate consistent output across production lines even under high pressures, continuous operation, or heavy workloads.

Food and Beverage Processing

In the food and beverage industry, hygiene and system dependability are critical. Pneumatic systems are preferred over hydraulic systems because of their cleanliness. However, even compressed air requires purification and pressure stabilization prior to use in clean zones.

Air filter regulators are essential for:

- Bottling and capping machines

- Conveyor control systems

- Pick-and-place packaging robots

- Pneumatic dosing systems

Regulators not only protect from contamination, but also prevent mechanical errors or sluggish cadence due to pressure changes. System stability, compromise sanitary compliance across all food-grade applications with high-quality air filter regulators and an experienced automation parts supplier is guaranteed.

Pharmaceutical and Cleanroom Manufacturing

Products manufactured in a cleanroom environment require compressed air of the highest purity. And in these environments, visibility of tools and assets is critical – which is why manufacturers are adopting cleanroom asset tracking for traceability and compliance. In pharmaceutical manufacturing where product precision is critical, even the slightest contamination can endanger whole batches especially when strict regulations governing consistency and compliance are observed.

Use of automation in medicine and pharmacy includes:

- Capsule filling machinery

- Clean air conveyors

- Sterile air control systems

- Fluid dispensing automation

In these settings, multi-stage air purification systems are quite common. An example of such a system would be the use of air filter regulators as the first line of defense. They perform rough filtration by removing particulates and setting a baseline pressure before the remaining filtration and drying processes. Downstream purification components are.. By using efficient regulators, smoother transitions between downstream pressure purifications is guaranteed.

Electronics Assembly and Semiconductor Fabrication

In manufacturing electronics and semiconductors parts, Precision electronics assembly together with semiconductor fabrication requires precision demanding processes: wafer manipulation laser testing surface mount technology surface mount technology assembly What makes these quadras hard to assemble stems from increasing miniaturization which calls for ultra-clean compressed air, precise flow rate regulation and strict monitoring.

Air filter regulators are used in:

- Pneumatic vacuum personnel carriers

- Test station actuators

- Micro-valve control units

Inconsistent air pressure may lead to inconsistent solder joints, loss of components or automated test failures. Dumping contaminated air during the operation runs the risk of permanently damaging microchips due to static charge build-up. That is why manufacturers turn to an automation parts supplier who understands the importance of high-performance components like air filter filter Regulator on critical applications

CNC Machining and Metal Fabrication

Shops that do machining and fabrication use compressed air to power grinders, air hammers, clamps, and robotic arms. Dust, oil, and moisture found in the atmosphere can damage precision components such as tools, systems, or parts.

Air filter regulators enhance:

- Aging of equipment

- Pneumatic clamps and jigs calibration accuracy

- Robotic loading arms movements

- Consistency of surfaces for finishing

By controlling compression, the torque & rotational speed of air tools are maintained at a specific level. This makes filter regulators especially useful when added by a trusted automation parts supplier familiar with the tough conditions on the manufacturing floor.

Agriculture and Food Packaging

There has been an increase in automation servicing agriculture industries like green houses, animal feeding systems to include packaging and sorting of crops using automated systems someone integrated outside or where dust or excessive moisture is present.

Air filter regulators are crucial for:

- Valves used in irrigation systems.

- Seeders that use pneumatic technology.

- Machines that pack crops.

- Systems for transporting grain.

These devices protect the environment from contaminants while air pressure stabilizing removes dust, pollen, and other particulates so that actuators and valves function with precision even under harsh conditions. Their rugged design ensures temperature fluctuations or changes in air quality won’t damage them when purchased through reputable automation parts suppliers.

Selecting the Best Air Filter Regulators

When selecting air filter regulators, the following details must be taken into consideration:

- Flow rate: Choose a unit rated for your system’s air volume.

- Micron Rating: 5-micron filters are finer; however, they increase pressure drop.

- Drain Type: Based on ease of access and maintenance preferences, drains can be manual, semi-auto, or fully automatic.

- Body material: Stainless steel is suitable for corrosive environments whereas aluminum is standard grade.

- Mounting and Space: Modular designs save space and ease system integration.

Your automation parts supplier should always be consulted to avoid issues like failing to pass industry custom-built equipment inspections or non-compliance to legal/in-house specifics regulations.—

Conclusion

Even though air filter regulators have a small size, their contribution to system optimization remains tremendous. From automotive production lines to cleanroom manufacturing, these devices safeguard systems, minimize downtime, and ensure stringent quality control – resulting in long-term cost savings.

With the right pairing of parts and recommendations from a well-versed automation parts supplier, industrial businesses are able to build clean, reliable, and performance optimised systems tailored to their needs.

For operations dependent on pneumatic power, protecting your investment by maintaining stable Clean Air is essential. An appropriate air filter regulator will enable you to achieve your production and quality benchmarks.